close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

In industrial lifting and modern logistics, choosing the right webbing-based lifting and cargo securing products is essential for both operational efficiency and safety. From factory lifting operations to long-distance transportation, webbing slings and cargo control products play a key role in protecting loads, improving handling efficiency and reducing on-site risks.

This article first introduces the main product systems commonly used in lifting and cargo securing applications, and then explains how a professional manufacturer supports these applications with stable quality and complete solutions.

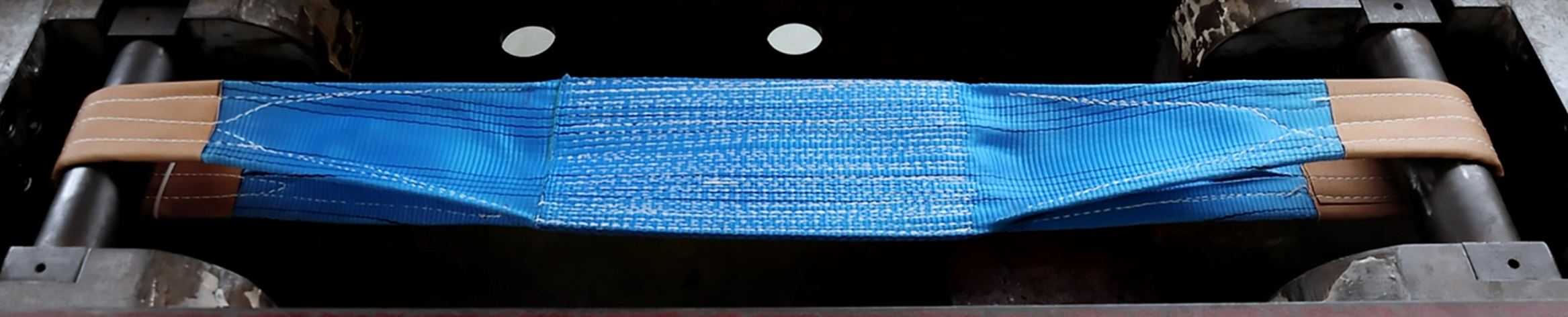

Webbing slings are widely used in workshops, construction sites and equipment installation projects. Their light weight and soft contact surface make them easy to handle while helping to protect the surface of the lifted load.

In daily operations, webbing slings are commonly selected when operators need:

• fast and simple rigging

• wide contact area on the load

• reduced surface damage compared with steel slings

Typical configurations include endless webbing slings and eye-and-eye webbing slings, which are suitable for most standard lifting tasks. In international projects, American standard webbing slings are often required to match local regulations and working practices.

Because webbing slings are flexible and easy to position, they are especially useful for lifting packaged goods, fabricated components and medium-weight equipment where frequent handling is required.

Round slings are designed for lifting loads that are heavy, irregular in shape or sensitive to surface pressure. Their internal polyester yarn core allows the sling to distribute load evenly around the entire loop.

Compared with flat webbing slings, round slings offer better shape adaptability and lower local pressure on the load surface. This makes them suitable for:

• machinery and equipment installation

• mold and tooling handling

• finished or coated products

Eye-eye round slings and American standard round slings are also commonly used when specific lifting configurations or market standards are required.

Behind every reliable sling and strap is stable and consistent webbing material.

Polyester webbing material is widely used for both lifting slings and cargo securing products because it provides:

• stable tensile strength

• controlled elongation

• good resistance to moisture and abrasion

Sling webbing material and lashing webbing material are produced for different application purposes. For projects serving the North American market, American standard webbing materials are often required to meet local technical specifications and performance expectations.

High-quality webbing material ensures consistent performance not only in finished slings and straps, but also for customers who manufacture or assemble their own products.

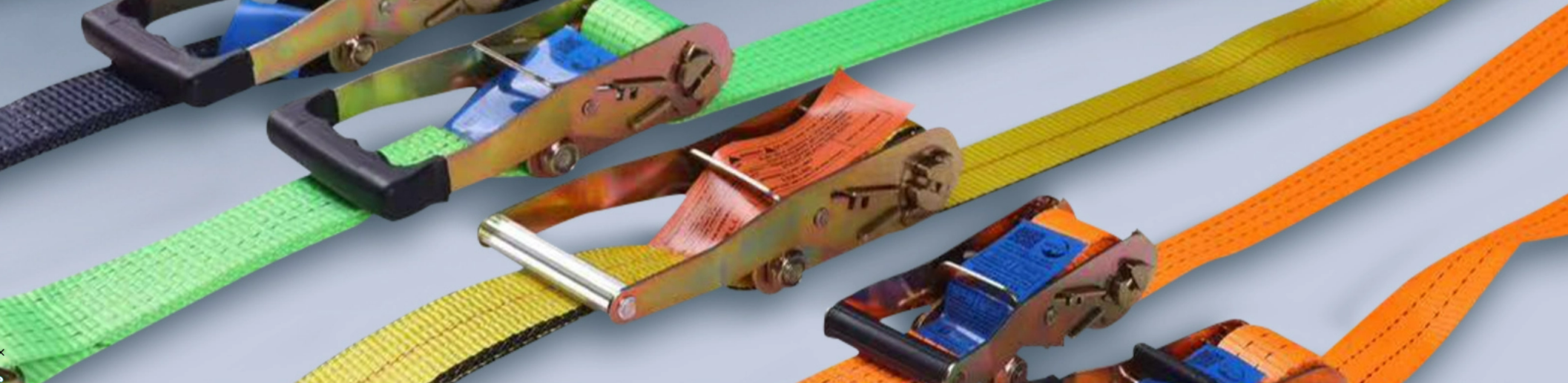

Cargo control products are essential for keeping goods stable during transportation.

Ratchet tie downs and winch straps are widely used on flatbed trailers, trucks and containers to restrain loads and prevent movement during transit. Cargo nets are commonly applied to cover or secure multiple items, improving safety and operational efficiency.

In daily logistics and transport operations, these products help:

• prevent load shifting and falling

• reduce transport damage

• improve compliance with transport safety regulations

For international fleets and overseas projects, American standard ratchet tie downs and related products are frequently specified.

To build complete and reliable systems, accessories such as cambuckles, ratchet buckles and hooks are equally important.

These components ensure proper connection, tensioning and load transfer between webbing products and the load or vehicle structure. Well-matched accessories improve ease of use and help maintain stable performance in long-term operations.

In lifting and cargo securing work, product performance directly affects operational safety.

Stable webbing strength, accurate load labeling, reliable stitching and consistent fittings help reduce uncertainty during use. When products are frequently exposed to outdoor environments, rough surfaces and repeated loading cycles, consistent manufacturing quality becomes even more critical.

This is why many distributors, lifting contractors and logistics companies prefer to work with manufacturers that can offer long-term product consistency and traceable quality control.

Supporting the above lifting and cargo control applications is NANJING D. L. T SLING Co., Ltd., a professional manufacturer and exporter specializing in webbing slings, round slings, polyester webbing materials and cargo control products.

Located in Nanjing, Jiangsu, China, the company focuses on the full production process of webbing and lifting products, from raw polyester yarn sourcing to weaving, dyeing, cutting, sewing and final inspection.

With more than 20 years of experience in the webbing and sling industry, the company supplies:

• webbing slings and round slings for lifting applications

• polyester webbing materials for sling and lashing production

• ratchet tie downs, winch straps and cargo nets for transport safety

• complete accessory solutions including buckles and hooks

Product safety is treated as the foundation of production.

From raw material selection to finished product delivery, strict process control and inspection procedures are applied at every stage. The manufacturing system supports stable output for both standard products and customized orders.

To support overseas customers and project users, the company also provides:

• pre-shipment inspection by photos or videos

• third-party inspection when required

• flexible customization for size, capacity, structure and labeling

Today, NANJING D. L. T SLING Co., Ltd. supplies products to customers in Europe, the United States, Australia, the Middle East and Southeast Asia, serving distributors, lifting service providers, construction companies and logistics operators.

Rather than offering only individual products, the company focuses on providing practical lifting and cargo securing solutions that match real working environments—helping customers improve safety, efficiency and long-term reliability in their daily operations.